Cold formed

Sheet Piles

IBO® The Tailor-Made Suit In The Sheet Pile World

The IBO® Sheet Piles are a new and improved type of Sheet Piles. With which weight advantages of up to 40% are possible.

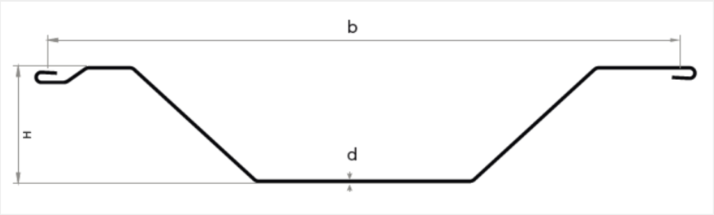

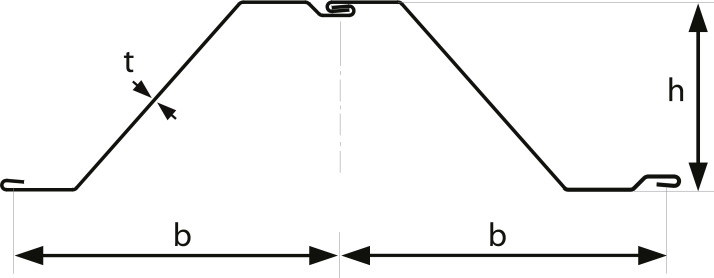

IBO® VKZ

The first Sheet Pile sections produced were narrow, thick, and heavy but with smart engineering and improved production facilities, we are now capable of producing wider and thinner sections. This results in more economic sections with less Lbs/Ft2 and less interlocks per wall feet which means less leakage risk and less interlocks to seal. Meever USA invented the “Precision Pile” to reduce costs and increase the capacity of a design. When designing a Sheet Pile Wall, come to Meever USA with your design parameters (S, I, thickness etc.) and we can provide a section unique to your job! This Unique concept allows you to save up to 20-40% of costs compared to current options on the market.

How does it work:

Meever USA creates a design which meets the required Section modulus/Moment of Inertia with multiple options determined by, Installation Technique, Tiebacks, Soil Conditions and Design Life. Another option is to send your already approved design to Meever USA. Its trained Engineers will prepare an Alternative Design for you to compare.

What makes the Precision Pile unique:

- In House Designing and Production;

- Custom shapes and measurements. Think about installing with a radius and any corner solution;

- The unique interlocks have less friction during installation and are more water-tight;

- Lighter per ft2/wall has compounding savings, less material costs, less transport, less handling and installation time;

- Available in small tonnages with no minimum order quantity;

- Larger effective width = fewer interlocks, which in turn would require less interlock sealant on watertight jobs;

- Lower emission values. We must highlight this in a way. Because less steel (20-40%) and transport (20-40%) and on top of that also the production is proven in a report that it saves 7% emission;

- Welding on anchor plates is easier and faster because an IBO® has no middle lock;

- Customizable to any layout;

- Increased pile driving efficiency.

Sheet Piling that in terms of dimensions, weight and technical specifications exactly match the strength and stiffness required in the specifications.

The Benefits:

- IBO® Sheet Piles are lighter than regular hot-rolled Sheet Piles;

- Well-nigh no lock friction in the sheet piles during installation;

- Many options in shapes and measurements;

- Create an angle without using loose corner sections;

- The locks are ideal for water-inhibiting products;

- Larger effective width = fewer interlocks;

- Less material = lower weight per ft2 and less CO2 emission;

- Suitable for smaller series;

- Fast delivery.

Meever USA optimizes the standard

Our IBO® profiles are developed by certified engineers whereby your requirements are the basis. We will develop the most advantageously profile with the required Moment of Inertia and Section Modulus. Your requirements regarding steel grade, thickness, width, and height will be considered in this development.

On demand you will receive a made-to-order profile which is especially developed for your project.